Learn the difference between the quality and care that goes into creating a custom-designed, one of a kind piece of jewelry, and "production grade" or "mass-produced" jewelry.

We will briefly follow the progress of THREE separate pieces of jewelry here, two rings and a pair of earrings, giving just the basics:

First, a sketch is made, translating the client's mental

image into a physical image. Multiple design options may be shown.

Next, a talented jewelry sculptor will take a square block

of carving wax, and turn the sketch which has been selected into a lifesize

duplicate

of the desired item. The hand carved wax will have to be perfect in every respect,

which is easier said than done.

We're looking here at beginning waxes for two different rings, one, with a single

large diamond will be in white gold,

a second ring, with three large diamonds will be done in Platinum, and lastly,

a pair of earrings which will also be done in white gold.

Below is one of the rings in progress:

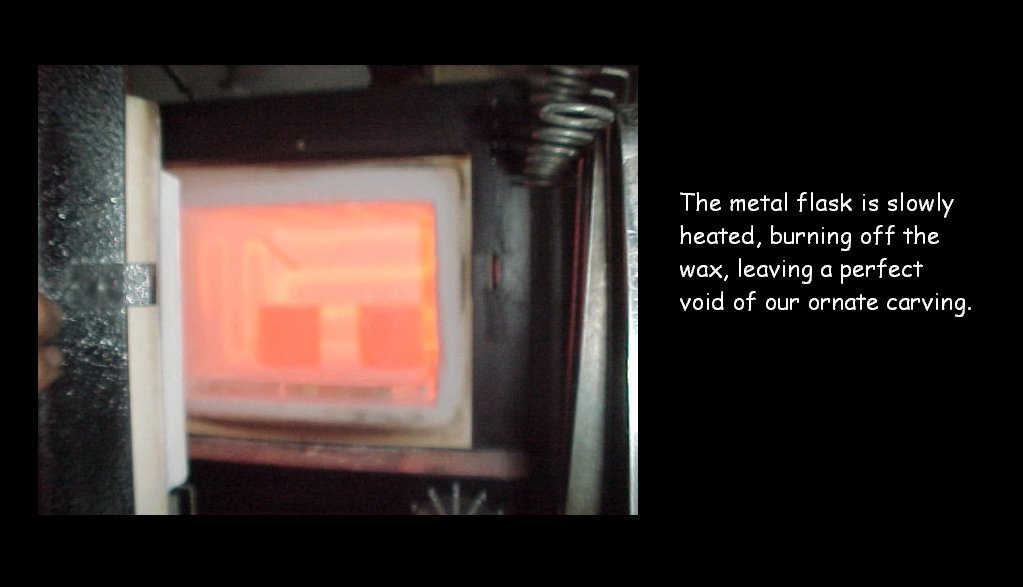

Wax carving is now "Sprued Up" wax vents shown in red help deliver the platinum

to the ring. A metal cylinder is added and sealed with wax to prevent the investment

mixture from leaking out. Paper cylinder is added for overflow of investment.

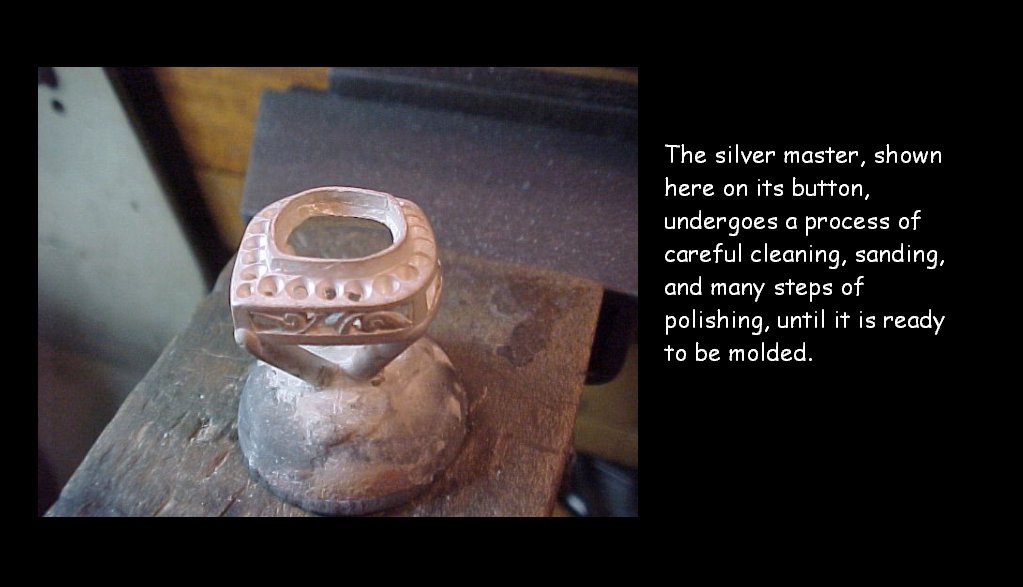

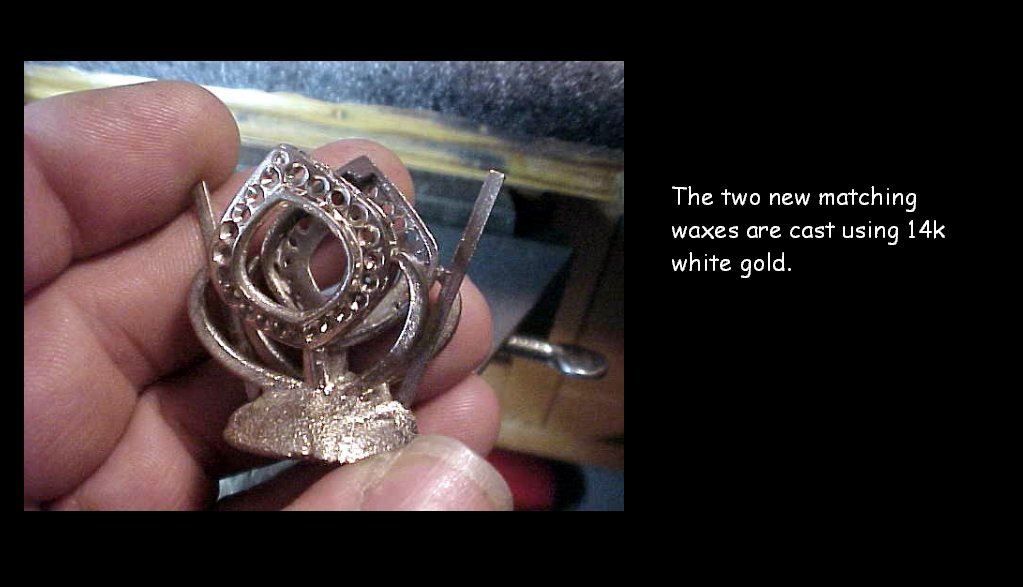

If the same design is to be used more than once (two earrings

which must exactly match, for example) an exact mold of the first will be made

from molten silver.

Some items of fine jewelry will be made of Gold, other items will be made of

Platinum.

Below is the amount of Platinum necessary to create a simple engagement and

wedding ring for a new bride.

There's almost $4000. worth of Platinum in this tiny little plastic bag.

Platinum (depending upon alloy used) is typically heated to 3224 degrees Farenheit,

making it a far more complex metal to work with.

Gold is heated to 1550 degrees.

Below is work underway on a pair of earrings

All Melee' (small diamonds) must be carefully measured before

Pave' setting (pave' means multiple diamonds set side by side so that the entire

surface appears to be covered with diamonds) . A lot of measuring and precise

layout work has occurred. Precision is a must, there are NO MISTAKES ALLOWED

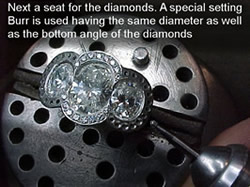

A layout is gently scribed on the work area. Pilot holes are drilled for each

diamond. "Seats" are drilled, (this is what the diamond sits on in the setting).

Shown below left, the Setting Burr, along with seats for

diamonds drilled to perfect height. Engravers are used to cut the setting Shown

a knife engraver, this one starts the cuts. Next will be a flat engraver to

"Bright Cut" the setting. Center diamond shows set accent diamonds, side diamond

is now ready for accent diamonds to be set.

This designer likes to use a 90 degree "V" engraver for the

corners. He raises a burr in all four corners. Now the "Burrs" are sharp so

he uses a Beading tool to make a little "Bead" out of the Burr The tip on the

beading tool is convex

|

Yes, here are even more pilot holes with seats. A lot more diamonds to go. All the holes add up. The integrity of the ring must be carefully planned to allow for the quantity of stones to be set. A careful balance of stability must be maintained. The structural integrity of the metal must not be compromised. This was carefully thought out while designing the ring. Much of the mass-produced micro-pave' work that we

see coming out of China and India today, have very small pave' set diamonds

which are set on top of the mounting without first drilling a seat. Although

the look is attractive, there is a serious problem. First, since the diamonds

are not properly secured, they often begin to dislodge within a matter

of weeks of everyday wear. Secondly, since no seat has been drilled, there

is no cleaning port for the reverse side of the diamond. Hand lotion or

other contaminants can become lodged under the stones. Why is this important?

Because when a repair needs to be made (resizing, re-tipping, or even

replacing a missing stone), if the diamonds are not totally clean on all

sides, the heat of a jewelers torch can inadvertantly destroy your diamonds.

Many jewelers don't want to waste several days working with acid just

to try to clean those diamonds before they can even work on your ring

(never a sure thing, anyway), and may simply decline to do repair work

on mass-produced micro-pave' diamond rings for this very reason. Others,

when selling this type of ring will add a disclosure, saying the ring

is not intended for daily wear, a disconcerting warning, particularly

when speaking of a wedding set. |

And here are the three final results:

BACK to TreasureCoastJewelers.com